Ensuring the quality of the logo printing on nonwoven shopping bags is important to create a professional and attractive promotional item.

Here are some tips to help you ensure the quality of the logo printing:

Choose a reputable supplier: Choosing a reputable supplier who specializes in nonwoven shopping bags with logo printing is important. Look for a supplier with a proven track record of quality printing and satisfied customers.

Provide high-quality artwork: Providing high-quality artwork to the supplier is important for ensuring the quality of the logo printing. Ideally, the artwork should be in a vector format, which will ensure that the logo looks sharp and clear even when enlarged.

Choose the right printing method: There are several different printing methods used for nonwoven shopping bags, such as screen printing, digital printing, and heat transfer printing. Each method has its own advantages and disadvantages, so it’s important to choose the method that best suits your logo and budget.

Use high-quality inks: Using high-quality inks is important for ensuring that the logo looks sharp and vibrant. Low-quality inks can fade or bleed over time, which can reduce the effectiveness of the promotional item.

Test the sample: Before placing a large order, it’s a good idea to order a sample to test the quality of the logo printing. china nonwoven machines supplier This will give you a chance to check the color accuracy, clarity, and durability of the printing.

By following these tips, you can ensure the quality of the logo printing on nonwoven shopping bags. A high-quality printed logo can help to create a professional and attractive promotional item that will effectively promote your brand.

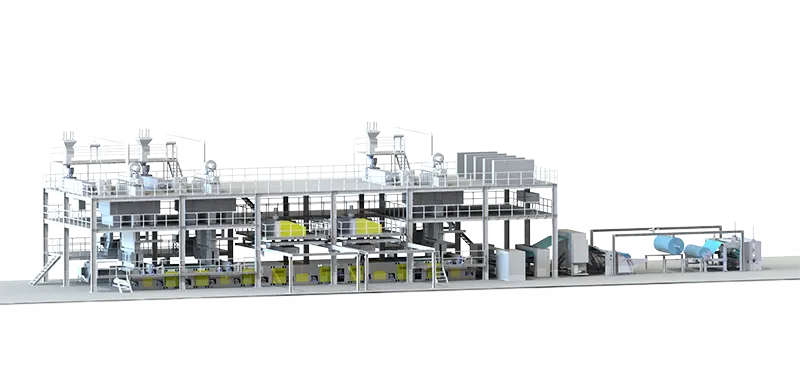

Why Are nonwoven machines So Popular?

Nonwoven machines are popular for several reasons, including:

Efficiency: Nonwoven machines are designed to produce nonwoven fabrics quickly and efficiently. They can produce large quantities of nonwoven fabrics in a short amount of time, making them a popular choice for manufacturers who need to produce fabrics quickly and at a low cost.

Versatility: Nonwoven machines can produce a wide range of nonwoven fabrics, including spunbond, meltblown, and needle-punched fabrics. This versatility makes them a popular choice for manufacturers who need to produce fabrics for a variety of applications.

Customizability: Nonwoven machines can be customized to produce nonwoven fabrics in a wide range of colors, weights, and textures. This allows manufacturers to create nonwoven fabrics that meet the specific needs of their customers.

Sustainability: Nonwoven machines are able to produce nonwoven fabrics using sustainable materials, such as recycled plastics and natural fibers. This makes them a popular choice for manufacturers who are looking for eco-friendly alternatives to traditional fabrics.

Cost-effectiveness: Nonwoven machines are able to produce nonwoven fabrics at a lower cost than traditional weaving or knitting machines. This makes nonwoven fabrics an affordable option for manufacturers who are looking to reduce their production costs.

Overall, nonwoven machines are popular due to their efficiency, versatility, customizability, sustainability, and cost-effectiveness. They are a popular choice for manufacturers who are looking to produce high-quality nonwoven fabrics quickly and at a low cost.