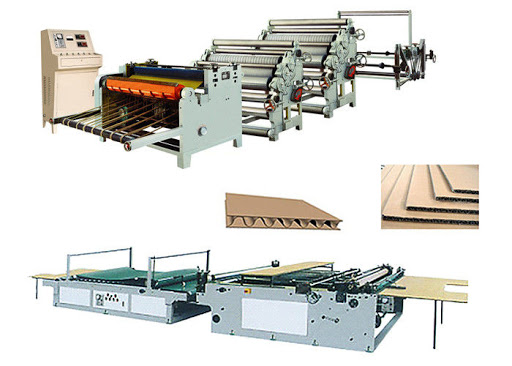

This helps us in controlling production costs and in providing excessive-high quality but reasonably priced machines. Beneath is a sample of the kind of machinery originally used in the manufacture of die cut and carton manufacturing. After the corrugator has heated, glued, and pressed the kraft paper to form corrugated cardboard, the continual sheet of cardboard is lower into vast box blanks that then go to different machines for printing, cutting, and gluing. Excessive precision, Excessive efficiency and High pace carton manufacturing period has come,so HOW to make it come true?By the efforts of all workers,we succeeded in finding a brand new path——Excessive Efficient Automated Carton Box Production Line. We can guarantee you product quality and aggressive price for Horizontal Automatic Small Sack Food Packing Machine, The product will provide to everywhere in the world, equivalent to: Japan , Ecuador , Leicester , With an increasing number of Chinese language merchandise all over the world, our worldwide business is creating quickly and financial indicators huge increase yr by yr. Solarco Short Run Corrugated Box Making Machinery. paper straw manufacturing machine

Carton box making machine market till 2021

This computerized BOXMATIC machine is ideal for the manufacturing of corrugated packing containers, trays, partitions and minimize-outs with the choice of additional die-cuts and flexo printing. Corrugated cardboard manufacture includes two key steps: making kraft paper and corrugating the cardboard. High effectivity: Produce as many as 600 PCS per minute and completed merchandise are counted mechanically. Greater than ninety five% of all merchandise in the United States are shipped in corrugated containers. Along with the amount and worth of the bins, the productiveness has also increased because of the elevated efficiency of corrugator machines. It exemplifies our dedication to producing and supplying the very best quality equipment to businesses across the world. The highest supplying international locations or regions are China, Malaysia, and India, which supply 99%, 1%, and 1% of carton field making machine costs respectively. Groups of salespeople and designers work together to create the manufacturing and printing patterns, known as dies, which are used to cut and print a specific field design. All of the processes are in our control, which incorporates the analysis and improvement, production, sales, and after-sales service. About 22% of those are carton printing slotting die-chopping machine, 18% are paper product making machinery, and 11% are packaging line. While another competing box firms are lumbered with outdated equipment that price more in labour to operate and lead to slower turnaround occasions, we make the job look straightforward by effortlessly operating our new and highly effective machines that produce equal or better high quality packing containers, in shorter turnaround times, and at decrease costs. The corrugator machine then cuts the board as many as 9 occasions, relying on the size of the box; that is decided by the FEFCO guide. One of the vital capabilities of a corrugated box is to supply crush resistance (product protection) and ample energy for stacking in warehouses. We provide packaging options for purchasers who need small quantity box orders shortly with any measurement box, additionally we are able to design the most appropriate resolution based on customer’s special requirements. That is anticipated to have a direct influence on the demand for shopper and end-consumer merchandise. Carton field making machine prices products are most popular in United States, Mexico, and India. Not solely does this present in our high quality of equipment, but also in the dedication and commitment we offer to each buyer. We develop and produce a broad vary of cardboard packaging solutions, tailored to your wants. The automatic BOXMATIC can also be geared up with two or three-out production and as much as three flexo print items and machine programming and parameter settings are quick and straightforward with the PLC contact panel. Thus, production of corrugated cardboard is steady, and no manufacturing velocity is misplaced. This market examine estimates that when it comes to geographic areas, APAC would be the major revenue contributor to the carton box making machine market till 2021. Our in-depth information and industrial expertise allow us to fabricate a distinguished range of Carton Field Making Machine. There are two varieties of chemical cooking, sulphite and sulphate, and each ends in better separation and reduction of lignin to supply higher high quality paper. Kline, James E. Paper And Paperboard: Manufacturing and Converting Fundamentals, 1991.

To analyse the Corrugated Field Making Machine market

Research analysis on the global corrugated field making machine market identifies that progress in e- commerce business will probably be one of many main factors that can have a positive influence on the growth of the market. If you are keen to get into the cardboard box manufacturing business, we consider it could be a worthwhile enterprise. Corrugated packaging is greatest suited to delivery and transporting various merchandise which are fragile in nature. 80% of business packaging is done by carton boxes on account of effective cushioning, light weight, easy to fabricate, easy for storing, simple for disposal, no strapping obligatory, printing and promoting advantages, should in export market, recyclable and so on. We focus on corrugated boxes, customized shows, labels, flexible packaging, folding cartons, inflexible containers, moving and shipping provides, and specialty and protective packaging. As a result of corrugated cardboard is such a flexible packaging materials, hundreds of thousands of tons are used every year to protect and show merchandise. Located in Faridabad (Haryana, India), we are a Sole Proprietorship agency engaged in providing a excessive-high quality range of merchandise. Boix delivers tray forming machines in Europe and is the market leader in forming and gluing both corrugated and strong board packaging. It starts by pulping wood chips utilizing a kraft course of; the preferred tree for the kraft paper is a pine tree. This manufacturing line contains three models:Printing Slotting Die-chopping Unit, Folding Gluing Unit, Stacking Unit(optional). T-ROC’s automated field making machines are designed to create customized on demand boxes of any dimension eliminating the necessity for packing peanuts, bubble wrap and different pointless fillers. Autobox is a subsidiary firm of Kolbus AutoBox, which began life within the UK, and was established to deliver field making machines to North America. To analyse the Corrugated Field Making Machine market based mostly on various components- worth analysis, provide chain evaluation, porter 5 drive analysis and many others. This trade is likely one of the vital customers of paperboard, producing bins and cartons for almost all varieties of industry available in the market. Vertical columns provide the very best field performance while interlocking patterns of boxes significantly cut back efficiency. The corrugated field market within the US mainly witnesses demand from the food and beverage trade. Like EMEA, the Americas witnessed a slow development within the demand for various services owing to the economic slowdown during 2012-2015. The Corrugated Box Making Machine trade report firstly introduced the Corrugated Field Making Machine Market fundamentals: type applications and market overview; product specifications; manufacturing processes; cost buildings, raw materials and so forth. Carton field making machine merchandise are hottest in United States, Mexico, and Bulgaria. Moreover, it is a B2B business, so, you must be capable to produce a large number of bins to meet giant orders from businesses. 7. The information supplied relies on a regular kind of producing exercise utilizing typical strategies of production at optimum level of performance. With a turnover of over 200 crores, SPB Machinery provides paper related machines for a wide range of products. However for top quality containers virgin Kraft continues to be used. Solarco Machinery was based in 1990 and specializes within the manufacturing of boxmaking machines designed for mid and brief runs. The beginning of 2016 witnessed a gradual increase within the demand for corrugated box making machines owing to the rise in the demand for packaging supplies,” provides Gaurav. For partition boxes the half slotted boards are used which can conveniently be produced over a partition spotter machines. Our team of in-home consultants provides specialised services that can bring your brand to life. International Corrugated Field Making Machine Market 2019report offers key statistics on the market standing of the Corrugated Box Making Machine Producers and is a precious source of guidance and route for companies and people involved in the Corrugated Field Making Machine Business.